Modern Methods of Construction

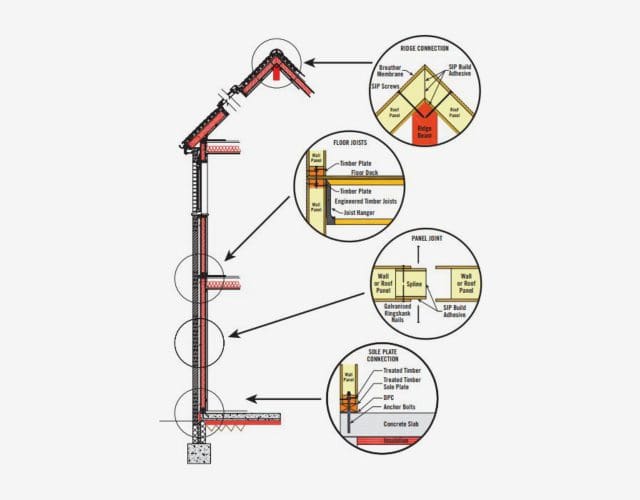

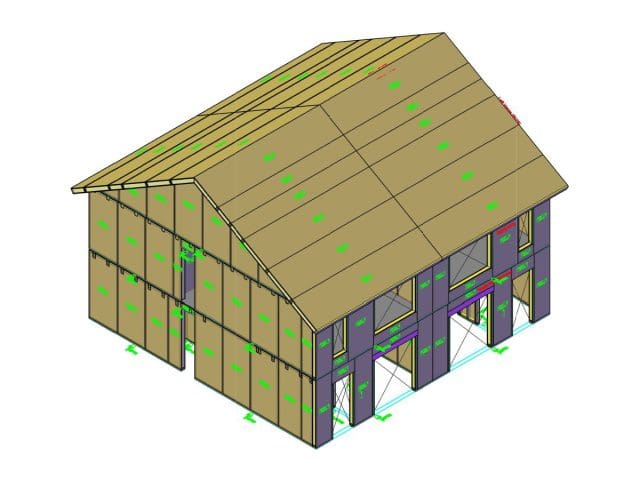

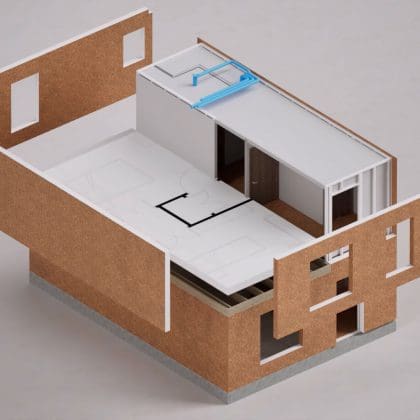

Adaptahaus is are experts in designing and delivering fully BBA-compliant wall, floor, and roof panels for various sectors and buildings. The product range includes Structural Insulated Panels (SIPS), timber stud internal panels, engineered floor joists, floor cassettes and prefabricated dormer window sets. We can also provide ancillary components such as decking, screws and fixings, breather membranes, adhesives and tapes.

Category 2 – Pre-Manufacturing – 2D primary structural systems

When most people hear “MMC,” their minds often jump straight to prefabrication or modular construction. However, modern methods of construction span a wide spectrum of techniques and innovations. We’ve seen firsthand that many professionals aren’t aware of the distinct categories that make up MMCs, and why this matters. In this article, we’ll explore the seven-category MMC definition framework developed by industry experts, providing clarity on how different approaches can impact your projects.

The MMC definition framework is designed to bring order to the evolving field of construction innovation. Developed by the MHCLG Joint Industry Working Group on MMC, with input from organisations such as Buildoffsite, Homes England, NHBC, and RICS, this framework categorises methods into seven distinct areas. Its purpose is twofold:

Category 2: Pre-manufacturing (2D Primary Structural Systems).

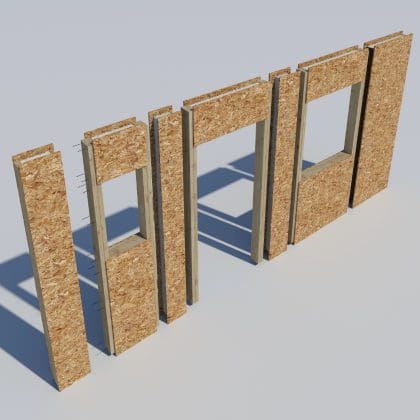

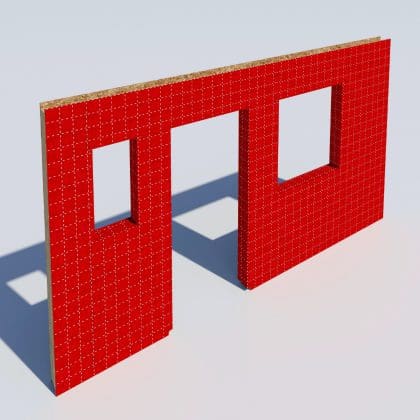

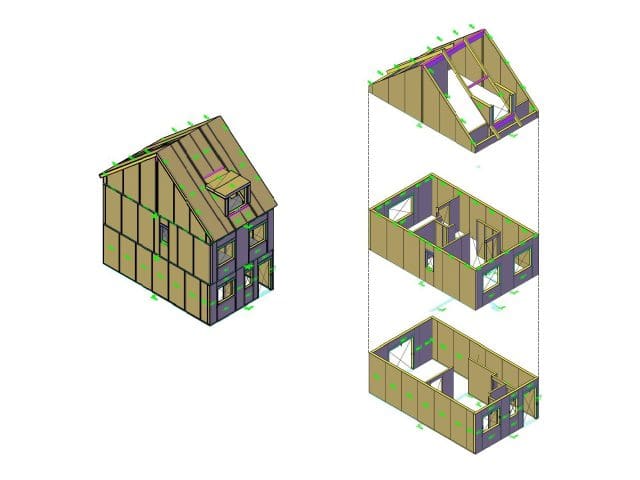

Category 2 is all about flat-panel systems. Here, pre-manufactured panels serve as the basic building blocks; walls, floors, roofs, that are later assembled on-site. This method generally involves less on-site assembly complexity than full volumetric systems.

Panel Types

Ranges from basic framing to enhanced panels that come with insulation, internal linings, or even complete external finishes.

On-Site Assembly

Panels are integrated at the construction site, which can streamline the building process and improve structural performance.

These are two dimensional panelised systems, manufactured in factories and assembled onsite to form a structure.

Category 2 systems have the ability to be manufactured to a client’s own individual designs and house types. They can provide bespoke solutions to sites that might already have planning, without housing organisations having to go back to the drawing board. 2D panelised systems are also easier to transport, so they are more suitable for sites with access issues.