Modern Methods of Construction

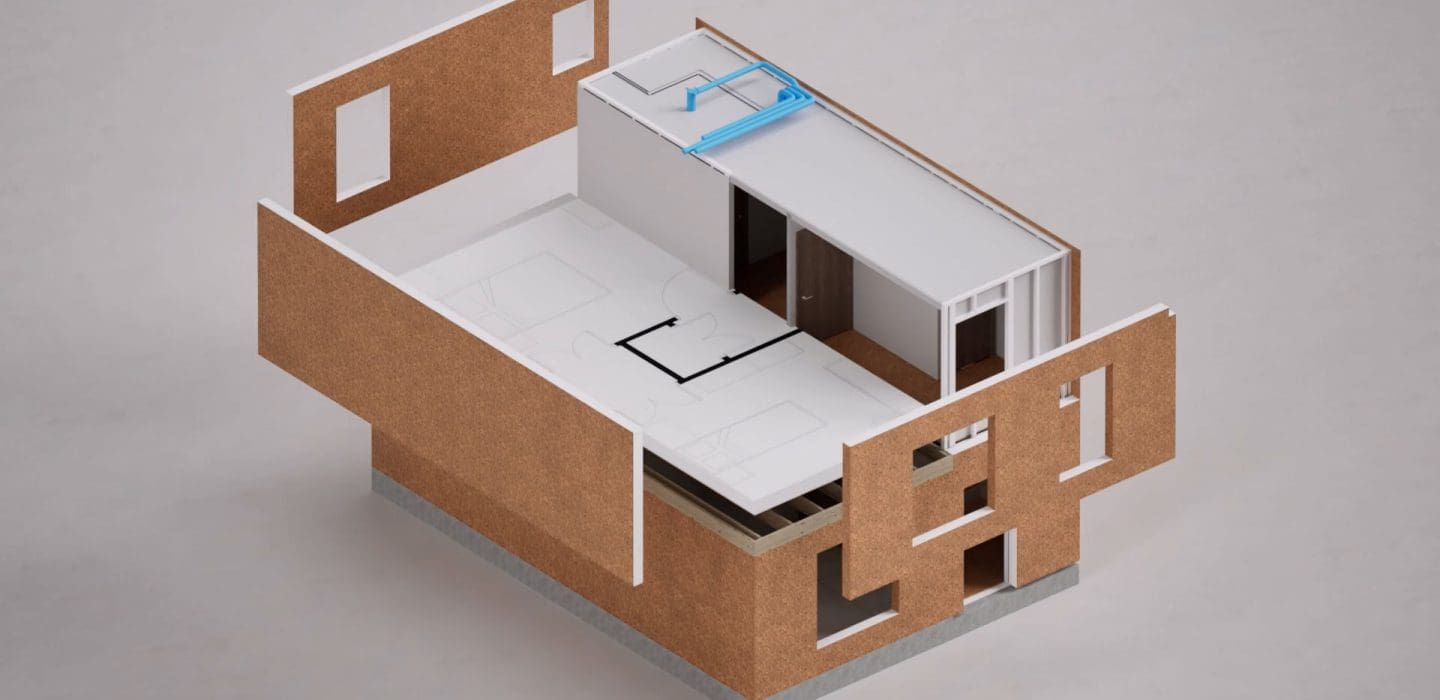

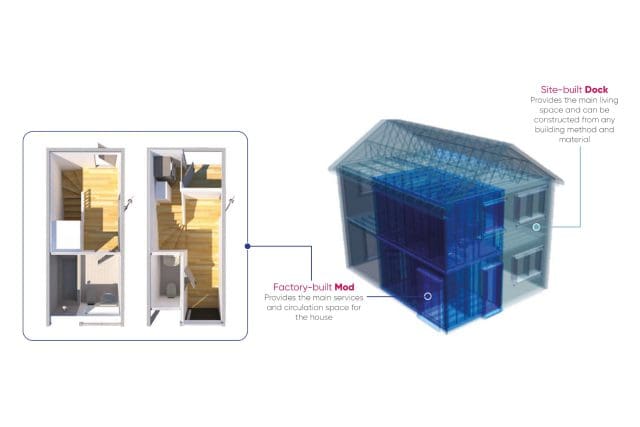

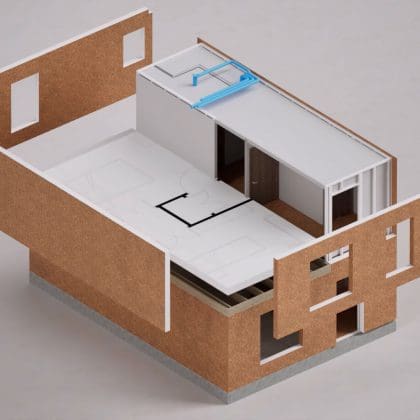

Hybrid Construction is a combination of MMC Categories 2 and 5 to reduce build time and increase ROIC using a panelised approach with PODS (bathrooms on suites) and PUC’s (Prefabricated Utility Cupboards)

MMC Category 2

Category 2 – Pre-Manufacturing (2D primary structural systems) are 2D panellised and framing systems. These are pre-manufactured and assembled on site to form the building. This covers basic framing only including walls, floors, stairs and roof structures. It also includes enhanced consolidation such as insulation, internal linings, external cladding etc.

MMC Category 5

Category 5 – Pre-Manufacturing (non-structural assemblies and sub-assemblies) includes the use of pre-assembled components that do not form the structure of the building but consolidates materials and processes that otherwise would have been completed on site. This includes whole bathroom, kitchen and M&E assemblies. It also covers panelised assemblies such as facades, roof structures, partition cassettes etc.

In Category 5, the focus shifts from primary structural elements to non-structural assemblies. This includes modular pods for bathrooms and kitchens, facade assemblies, roof cassettes, and even integrated M&E (mechanical and electrical) systems.

Specialised Modules

These assemblies can be prefabricated and later integrated into larger construction projects.

Enhanced Quality

By pre-manufacturing these sub-assemblies, consistency and quality can be maintained while reducing on-site labour. This category showcases the potential to offload a significant portion of on-site work to the controlled environment of a factory.